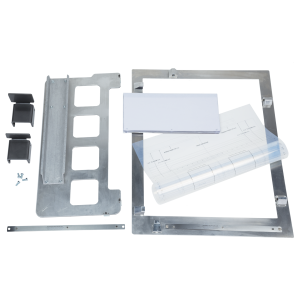

PRE-REGISTRATION SYSTEM

Built for speed and accuracy, our system makes pre-registering your screens easier than ever. Simple to learn & use, anybody can be trained to quickly align multi color prints. The Workhorse Pre-Registration System is compatible with all Workhorse Screen Printing Presses and may be used with wood frames, aluminum frames and roller frames. Eliminating costly setups will have you making a return on your investment in no time.

- 4 Sizes of Complete Registration Package

- Compatible with all Workhorse Printing Presses

- Kit Includes: Exposure Frame, Registration Pallet, Stop Brackets, Carrier Sheets, Layout Sheet, Registration Pin Bar and Hex Bolts

SD-10 SERIES SCREEN DRYING CABINET

This unit is designed to eliminate problems associated with the screen preparation process. Problems such as dust and foreign materials caught in the emulsion, the application of block out and labor costs to repair pinholes and imperfections, and inconsistent drying times to name a few. The SD-10 will save you time, money and improve your overall screen quality. It’s versatility to hold a variety of screen sizes, function as a perfect stand for most bench model exposure units and affordable price, make it a welcome addition to any print shop.

- 10-screen capacity from 20″ x 24″ up to 25″ x 36″

- Digital Temperature Control

- Dual Functioning Exhaust

The SD-10 is the perfect size to allow the Lumitron MDLUM-LED 25″ x 36″ exposure unit to fit on top.

STAMPINATOR 480

The Stampinator 480 allows you to produce specialty prints in one application. Our high volume in-line heat press inserts directly into your Workhorse Automatic Press and produces over 480 units per hour.

- Stamping & Matting Fibers

- Heat Transfers

- Stamping the Underbase

- Screen Numbers

- Rhinestones

- Heat Tapping

- Cad-Cut Vinyl

- Twill

- Foil

WASH-IT

Available in two sizes, the Wash-It is ideal for developing and reclaiming your screens. Designed to work at waist height, these sinks are ergonomically built for function and comfort.

- Large Screen Capacity

- Multiple Screen Capacity

- Solid, Waterproof Steel Construction

- Translucent Back Window

- Adjustable Screen Racks

- Easy and Thorough Drainage

ACCU-STRETCH

Printing at higher, uniform tensions provides faster production speeds, improved registrations, longer screen and squeegee life, more consistent ink deposits and lower ink usage. The patented Accu-Stretch provides these benefits while eliminating complicated stretching systems, training and expensive tools. Self-equalizing stretch clamps provide uniform tension while minimizing fabric waste by enabling you to stretch directly from the fabric bolt. The modular design enables Accu-Stretch to be expanded to virtually any size and width of fabric and frame materials.

- 9 sizes of complete Accu-Stretch systems

- 5 sizes of Accu-Stretch Upgrades

- Adjustable down to 10″ x 15″ (24x38cm)

- Infinite independent warp and weft tension controls

- Brace-bar pre-bows- frame

- Self-equalizing clamps for even tension

- Compatible with all stretch and glue frames